Week 9 - Proposal Presentation

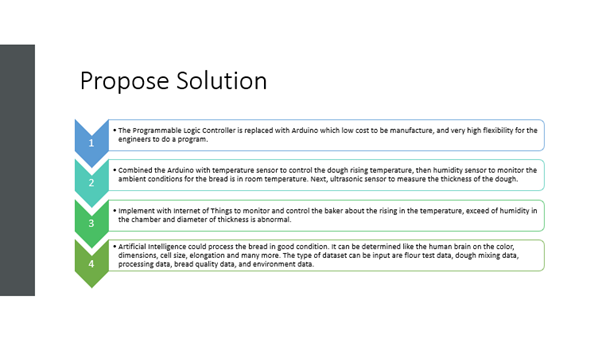

For this week, Sir Zaki was given to us for researching on startup of the technology machine. This technology machine needs to improve from a Programmable Logic Controller to a microcontroller. The microcontroller would combine with the sensor, Internet of Things (IoT), machine learning or Artificial Intelligence into the project.

A Programmable Logic

Controller, or PLC, is a ruggedized computer used for industrial automation.

These controllers can automate a specific process, machine function, or even an

entire production line. The PLC receives information from connected sensors or

input devices, processes the data, and triggers outputs based on pre-programmed

parameters.

Depending

on the inputs and outputs, a PLC can monitor and record run-time data such as

machine productivity or operating temperature, automatically start and stop

processes, generate alarms if a machine malfunctions, and more. Programmable

Logic Controllers are a flexible and robust control solution, adaptable to

almost any application.

PLC control system is that it regards PLC as a control key

component, utilize special I/O module to form hardware of control system with a small amount of measurement and peripheral circuit, to realize control to the whole system through programming.

1. High Reliability

Strong anti-interference quality and very high reliability are the

most important features of PLC. To make PLC work stably in strong

interferential circumstances. Many techniques are applied in PLC. Software

control instead of relay control mode can decrease faults that are brought

about by the original electric contact spot outside working badly. Industrial-grade

components made by advanced processing technology can resist interference, and

self-diagnosis measures of watchdog circuits for protecting memory can improve the performance of PLC greatly.

2. Good Flexibility

There are several programming languages for PLC including ladder

diagram, SFC, STL, ST, and so on. If the operator can master only one of the programming

languages, he can operate PLC well. Every who wants to use PLC has a good

choice. Based on engineering practice, capacity and function can be expanded by

expanding the number of modules, so PLC has good flexibility.

3. Quality of Strong Easy-Operating

It is very easy to edit and modify programs for PLC by computer offline or

online. It is very easy to find out where the fault lies by displaying the

information of fault and function of Self Diagnosing Function, and all these

make maintenance and repair for PLC easier. It is very easy to configure a PC

because of modularization, standardization, serialization of PLC.

Advantages of using PLC:

- Small physical size & shorter project

time.

- Cost-effective for controlling complex systems.

- Reliability.

- Less and simple wiring.

- Faster response.

- Remote control capability.

- More flexibility.

- Ease of maintenance/troubleshooting.

Disadvantages of using PLC:

- Fixed circuit operation.

- PLCs manufacturers offer only closed loop

architecture.

- PLCs are propitiatory, which means software

and parts one manufacturer cannot be easily used in combination with part

of another manufacturer.

- Number of optional modules must be added to

maximize flexibility and performance.

Improvement from Industrial Revolution 3.0 to Industrial 4.0

Industrial Revolution 4.0 is coined

in 2011, representing the role that cyber-physical system (CPS), cloud computing, The Industrial Internet of Things (IIOT) will have on the manufacturing process.

The difference between Industry 3.0 and Industry 4.0 that in Industry 3.0, the

automated processes using logic processors and information technology. These

processes often operate primarily without human interference, but there is

still a human aspect behind them. Industry 4.0 comes in with the availability

and use of vast quantities of data on the production floor.

An example of the old way (Industry

3.0) is taking a CNC machine: while largely automated, it still needs input

from a human controller. The process is automated based on human information,

not by data. Under Industry 4.0, that same CNC machine would be able to follow

set programming parameters and use data to streamline production processes.

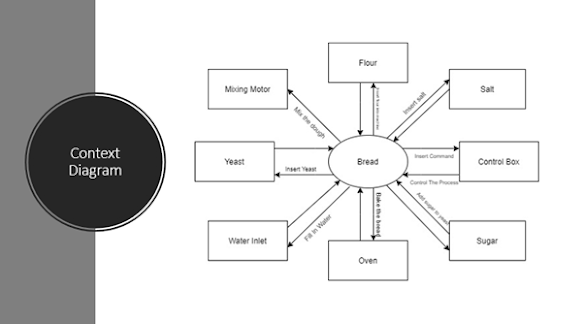

Thus, in our project, we need to

implement system PLC replacement to new technology that is more productive,

convenient to maintenance, and cost-effective to implement. For the proposed

improvement technology that we selected is a dough machine mixer.

Improvement System from PLC to

Microcontroller Arduino

Comments

Post a Comment